Renegade Manufacturing

ManufacturingState-of-the-Art Machine Shop Facilities

Our facility is outfitted with an array of advanced manufacturing technologies, including several programmable mills, grinders, and welding machines, alongside a variety of manually operated equipment. This combination allows us to offer unparalleled precision and flexibility in production.

Shop Capabilities

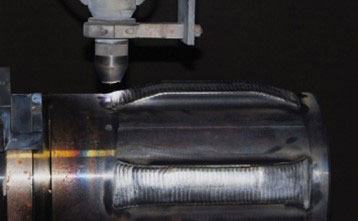

PTA Welding

Renegade’s welding facility is equipped to lay carbide-based hard metal on wear pads, drive coupling lobes, and stabilizers. Our PTA machines can produce uniform wear pads with consistent thickness. Renegade is also capable of centrifugal casting of internal bearings.

At the heart of our operations is a welding unit specialized in applying carbide-based hard metal to critical wear areas such as wear pads, drive coupling lobes, and stabilizers. Thanks to our precision PTA (Plasma Transferred Arc) machines, we ensure each wear pad is uniformly coated with a consistent thickness, enhancing durability and performance.

Shot Peening

Renegade’s shot peen process is used to reduce surface cracking on parts with areas of high stress concentration, such as threaded connections, radii, sharp corners, etc. This relieves residual stress and can reduce the occurrence of fatigue cracking in highly stressed parts.

Phosphate Coating

Renegade has zinc phosphating capabilities, helping the parts to retain oil and lubricating compounds to prevent corrosion and thread galling.

Furthermore, our facility is equipped with zinc phosphating capabilities, a critical treatment that allows parts to better retain oil and lubricating compounds. This not only prevents corrosion but also minimizes the risk of thread galling, ensuring our products maintain their integrity and performance over time.

Radial Bearing Manufacturing

Renegade Manufacturing engineered proprietary carbide-tiled radial bearings for drilling motors. These new and improved radial bearings are a significant improvement over the standard carbide powder type radial bearing coating.

Our radial bearings use multiple carbide tiles arranged on both the male and female sleeves to create a superior radial bearing. The carbide tiles are surrounded by a nickel/chrome/silicon/boron powder matrix.

• Lowest coefficient of friction

• 4-6x bearing life providing increased motor reliability

• Consistent build rates

• Longer motor runs

Other Capabilities

– Full Quality Control

– Cast (Induction)

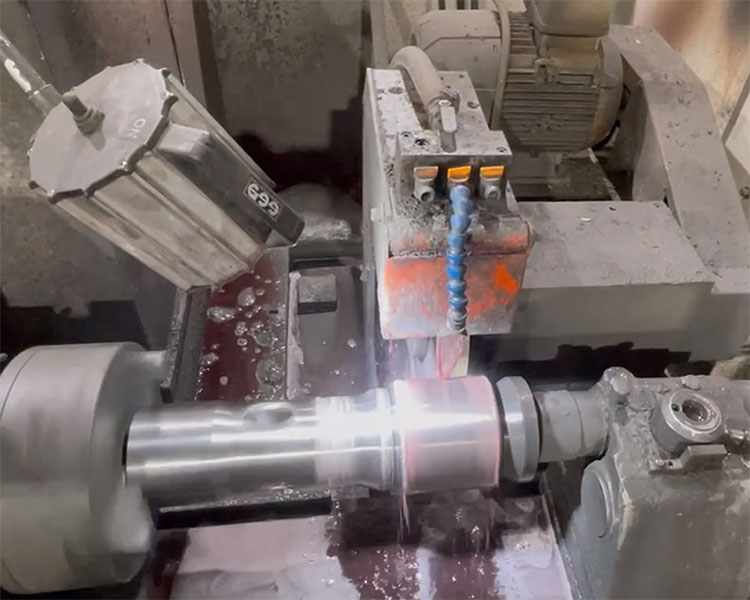

– Milling

– Honing

– ID Grinding

– OD Grinding

– Saw Cutting

– QT lathes

– Flat Bed Lathes

– Titanium milling: Titanium Flex shafts

Machinery & Equipment

– Induction Casting units

– PTA Welders

– M5 Lathe

– Power Masters Lathes

– 350 QT CNC Lathes

– 250 QT CNC Lathe

– 550 QT CNC Lathe

– Saws

– I.D. Hones

– ID Grinders

– OD Grinders

– Machining Centers

– 450 Short Bed Lathe

– 450 Long Bed Lathe

Learn More or Get Started Today

Discover how Renegade Manufacturing can optimize your operations with expertly engineered drilling motor parts. Explore the possibilities, request a consultation, or reach out to our team of experts for more details.

Let's engineer success together.